- HOME

- PRODUCTS

PRODUCTS

- About Us

About Us

- DEALER LOCATOR

- TESTING IN HIMALAYA INITIATIVE

- PRODUCT TESTING

PRODUCT TESTING

- CSR

-

0₹0.00

- No products in the cart.

-

0₹0.00

- No products in the cart.

- HOME

- PRODUCTS

PRODUCTS

- About Us

About Us

- DEALER LOCATOR

- TESTING IN HIMALAYA INITIATIVE

- PRODUCT TESTING

PRODUCT TESTING

- CSR

ROCK ANCHORS

Showing all 13 results

-

This pack has been put together keeping Badami climbing season in India in mind. The pack includes the following equipment

5 pcs. M10 Dynamo Rock Hanger (Material grade: SS 304)

5 pcs. M10 Nuts only (Material grade: SS 304)

1 pc. Badami Nut Tool

Hangers have EN959 and CE 3076 certification

Breaking Strength of Hangers: 32kN in Radial direction of loading -

One Tool to rule them all!

A versatile nut tool designed for Trad, mixed- Sport and Big Wall climbing. Tightens nuts and maillons, wriggles out those obstinate nuts, and the hooked nose grabs onto cam bars in the deepest cracks. The screw driver end helps undo those stubborn knots, works as a pry tool, and finding an additional new use for this multi-tool is not a challenge.

– Weight: 64 g (2.3 oz.)

– Material: Zinc plated hardened Steel

– Built in wrenches of sizes 13, 17 & 19 mm, which work with 10, 12 mm & 3/8 inch Rawl bolts, open wrench sizes 14 & 17mm

– Philips head screw driver

– Centimeter markings along the side -

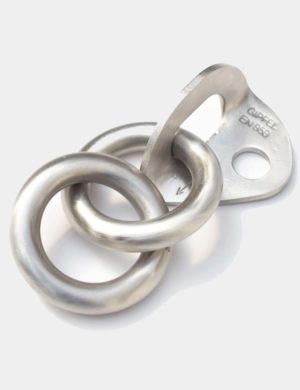

– Double rings anchors available in SS 316 (for M12 bolts) and SS 304 (for M10 bolts) grades

– Our regular Dynamo rock anchor conforms to EN 959:2016 and CE 3076

– MBS (rings): 30 kN

-

Dynamo Expansion Bolt, M10X100mm, SS304, for rock anchors.

-

– Stainless Steel 304 wedge type expansion bolts for outdoor use (not marine grade).

– Diameter: 10mm

– Placement length: 62mm

– Recommended length of bore in rock: 70mm

– Choose the bolt size carefully depending upon strength of base rock material. If the rock is soft or has uneven composition such as Sandstone and Limestone, then any rock anchor, including ours will not be strong enough to endure heavy loading.

– This anchor is not recommended for use in coastal areas because it may not last as long as it normally should. For areas within 100 kms of coastline we recommend the anchors must be made in marine grade Stainless Steel. Contact us if you want these to be custom made!

– If you are combining our bolts with hangers from another manufacturer, then ensure that they are made from the same grade of metal.The recommendation below is based on several assumptions. Do your own due diligence before installing an anchor anywhere.

M10 bolt: Only to be used in very hard rocks such as Granite (Compressive Strength > 75MPa)

M12 Bolt: Only to be used in medium to high hardness rocks such as Sandstone (Compressive Strength > 30MPa)– EN959:2007, CE3076

- Minimum Breaking Strength of Hanger is 25kN. Although the older versions are marked with 22kN, we guarantee 25kN.We take factor of safety into account with this figure of 25kN. Gipfel hangers are tested for breaking load often and none of them has ever failed under 38kN (the average breaking load has been 40kN) in both recommended direction of loading (radial) as well as in axial direction (Tensile)

- Cutting Strength (Radial Load) in 50MPA test concrete block: 25kN (For Both M10 & M12 Sizes)

- Pull-out strength (Axial load) in 50MPA test concrete block: 25kN (for M12 bolt) and 15kN (for M10 bolt)

User Instructions

Download the PDF

Download the PDF

User Instructions Download the PDF

Download the PDF -

– Stainless Steel 304 wedge type expansion bolts for outdoor use (not marine grade).

– Diameter: 12mm

– Placement length: 87mm

– Recommended length of bore in rock: 95mm

– Choose the bolt size carefully depending upon strength of base rock material. If the rock is soft or has uneven composition such as Sandstone and Limestone, then any rock anchor, including ours will not be strong enough to endure heavy loading.

– This anchor is not recommended for use in coastal areas because it may not last as long as it normally should. For areas within 100 kms of coastline we recommend the anchors must be made in marine grade Stainless Steel. Contact us if you want these to be custom made!

– If you are combining our bolts with hangers from another manufacturer, then ensure that they are made from the same grade of metal.The recommendation below is based on several assumptions. Do your own due diligence before installing an anchor anywhere.

M10 bolt: Only to be used in very hard rocks such as Granite (Compressive Strength > 75MPa)

M12 Bolt: Only to be used in medium to high hardness rocks such as Sandstone (Compressive Strength > 30MPa)– EN959:2007, CE3076

- Minimum Breaking Strength of Hanger is 25kN. Although the older versions are marked with 22kN, we guarantee 25kN.We take factor of safety into account with this figure of 25kN. Gipfel hangers are tested for breaking load often and none of them has ever failed under 38kN (the average breaking load has been 40kN) in both recommended direction of loading (radial) as well as in axial direction (Tensile)

- Cutting Strength (Radial Load) in 50MPA test concrete block: 25kN (For Both M10 & M12 Sizes)

- Pull-out strength (Axial load) in 50MPA test concrete block: 25kN (for M12 bolt) and 15kN (for M10 bolt)

User Instructions

Download the PDF

Download the PDF

User Instructions Download the PDF

Download the PDF -

– Stainless Steel 316 wedge type expansion bolts for outdoor use (marine grade).

– Diameter: 12mm

– Placement length: 87mm

– Recommended length of bore in rock: 95mm

– Choose the bolt size carefully depending upon strength of base rock material. If the rock is soft or has uneven composition such as Sandstone and Limestone, then any rock anchor, including ours will not be strong enough to endure heavy loading.

– This anchor is not recommended for use in coastal areas because it may not last as long as it normally should. For areas within 100 kms of coastline we recommend the anchors must be made in marine grade Stainless Steel. Contact us if you want these to be custom made!

– If you are combining our bolts with hangers from another manufacturer, then ensure that they are made from the same grade of metal.The recommendation below is based on several assumptions. Do your own due diligence before installing an anchor anywhere.

M10 bolt: Only to be used in very hard rocks such as Granite (Compressive Strength > 75MPa)

M12 Bolt: Only to be used in medium to high hardness rocks such as Sandstone (Compressive Strength > 30MPa)– EN959:2007, CE3076

- Minimum Breaking Strength of Hanger is 25kN. Although the older versions are marked with 22kN, we guarantee 25kN.We take factor of safety into account with this figure of 25kN. Gipfel hangers are tested for breaking load often and none of them has ever failed under 38kN (the average breaking load has been 40kN) in both recommended direction of loading (radial) as well as in axial direction (Tensile)

- Cutting Strength (Radial Load) in 50MPA test concrete block: 25kN (For Both M10 & M12 Sizes)

- Pull-out strength (Axial load) in 50MPA test concrete block: 25kN (for M12 bolt) and 15kN (for M10 bolt)

User Instructions

Download the PDF

Download the PDF

User Instructions Download the PDF

Download the PDF -

– Stainless Steel 304 Rock hangers for outdoor use (not marine grade).

– Bore diameter: 10mm

– This hanger features chamfered edges of the eye hole to minimize wear on carabiner. The eye hole itself is large enough to accommodate two carabiners.

– Choose the bolt size carefully depending upon strength of base rock material. If the rock is soft or has uneven composition such as Sandstone and Limestone, then any rock anchor, including ours will not be strong enough to endure heavy loading.

– This anchor is not recommended for use in coastal areas because it may not last as long as it normally should. For areas within 100 kms of coastline we recommend the anchors must be made in marine grade Stainless Steel. Contact us if you want these to be custom made!

– If you are combining our hangers with your own bolts, ensure that they are made from the same grade of metal.

– Each hanger is tested at a proof load of 8kN before shipping. You will be able to see a very small indentation on the side of the eye-hole. That is because it was tested in our lab for your safety.The recommendation below is based on several assumptions. Do your own due diligence before installing an anchor anywhere.

M10 bolt: Only to be used in very hard rocks such as Granite (Compressive Strength > 75MPa)

M12 Bolt: Only to be used in medium to high hardness rocks such as Sandstone (Compressive Strength > 30MPa)– EN959:2007, CE3076

- Minimum Breaking Strength of Hanger is 25kN. Although the older versions are marked with 22kN, we guarantee 25kN. We take factor of safety into account with this figure of 25kN. Gipfel hangers are tested for breaking load often and none of them has ever failed under 38kN (the average breaking load has been 40kN) in both recommended direction of loading (radial) as well as in axial direction (Tensile).

- Cutting Strength (Radial Load) in 50MPA test concrete block: 25kN (For Both M10 & M12 Sizes)

- Pull-out strength (Axial load) in 50MPA test concrete block: 25kN (for M12 bolt) and 15kN (for M10 bolt)

User Instructions

Download the PDF

Download the PDF

User Instructions Download the PDF

Download the PDF -

– Pack of 5

– Stainless Steel 304 Rock hangers for outdoor use (not marine grade).

– Bore diameter: 10mm

– This hanger features chamfered edges of the eye hole to minimize wear on carabiner. The eye hole itself is large enough to accommodate two carabiners.

– Choose the bolt size carefully depending upon strength of base rock material. If the rock is soft or has uneven composition such as Sandstone and Limestone, then any rock anchor, including ours will not be strong enough to endure heavy loading.

– This anchor is not recommended for use in coastal areas because it may not last as long as it normally should. For areas within 100 kms of coastline we recommend the anchors must be made in marine grade Stainless Steel. Contact us if you want these to be custom made!

– If you are combining our hangers with your own bolts, ensure that they are made from the same grade of metal.

– Each hanger is tested at a proof load of 8kN before shipping. You will be able to see a very small indentation on the side of the eye-hole. That is because it was tested in our lab for your safety.The recommendation below is based on several assumptions. Do your own due diligence before installing an anchor anywhere.

M10 bolt: Only to be used in very hard rocks such as Granite (Compressive Strength > 75MPa)

M12 Bolt: Only to be used in medium to high hardness rocks such as Sandstone (Compressive Strength > 30MPa)– EN959:2007, CE3076

- Minimum Breaking Strength of Hanger is 25kN. Although the older versions are marked with 22kN, we guarantee 25kN. We take factor of safety into account with this figure of 25kN. Gipfel hangers are tested for breaking load often and none of them has ever failed under 38kN (the average breaking load has been 40kN) in both recommended direction of loading (radial) as well as in axial direction (Tensile).

- Cutting Strength (Radial Load) in 50MPA test concrete block: 25kN (For Both M10 & M12 Sizes)

- Pull-out strength (Axial load) in 50MPA test concrete block: 25kN (for M12 bolt) and 15kN (for M10 bolt)

User Instructions

Download the PDF

Download the PDF

User Instructions Download the PDF

Download the PDF -

– Stainless Steel 304 Rock hangers for outdoor use (not marine grade).

– Bore diameter: 12mm

– This hanger features chamfered edges of the eye hole to minimize wear on carabiner. The eye hole itself is large enough to accommodate two carabiners.

– Choose the bolt size carefully depending upon strength of base rock material. If the rock is soft or has uneven composition such as Sandstone and Limestone, then any rock anchor, including ours will not be strong enough to endure heavy loading.

– This anchor is not recommended for use in coastal areas because it may not last as long as it normally should. For areas within 100 kms of coastline we recommend the anchors must be made in marine grade Stainless Steel. Contact us if you want these to be custom made!

– If you are combining our hangers with your own bolts, ensure that they are made from the same grade of metal.

– Each hanger is tested at a proof load of 8kN before shipping. You will be able to see a very small indentation on the side of the eye-hole. That is because it was tested in our lab for your safety.The recommendation below is based on several assumptions. Do your own due diligence before installing an anchor anywhere.

M10 bolt: Only to be used in very hard rocks such as Granite (Compressive Strength > 75MPa)

M12 Bolt: Only to be used in medium to high hardness rocks such as Sandstone (Compressive Strength > 30MPa)– EN959:2007, CE3076

- Minimum Breaking Strength of Hanger is 25kN. Although the older versions are marked with 22kN, we guarantee 25kN. We take factor of safety into account with this figure of 25kN. Gipfel hangers are tested for breaking load often and none of them has ever failed under 38kN (the average breaking load has been 40kN) in both recommended direction of loading (radial) as well as in axial direction (Tensile).

- Cutting Strength (Radial Load) in 50MPA test concrete block: 25kN (For Both M10 & M12 Sizes)

- Pull-out strength (Axial load) in 50MPA test concrete block: 25kN (for M12 bolt) and 15kN (for M10 bolt)

User Instructions

Download the PDF

Download the PDF

User Instructions Download the PDF

Download the PDF -

– Pack of 5

– Stainless Steel 304 Rock hangers for outdoor use (not marine grade).

– Bore diameter: 12mm

– This hanger features chamfered edges of the eye hole to minimize wear on carabiner. The eye hole itself is large enough to accommodate two carabiners.

– Choose the bolt size carefully depending upon strength of base rock material. If the rock is soft or has uneven composition such as Sandstone and Limestone, then any rock anchor, including ours will not be strong enough to endure heavy loading.

– This anchor is not recommended for use in coastal areas because it may not last as long as it normally should. For areas within 100 kms of coastline we recommend the anchors must be made in marine grade Stainless Steel. Contact us if you want these to be custom made!

– If you are combining our hangers with your own bolts, ensure that they are made from the same grade of metal.

– Each hanger is tested at a proof load of 8kN before shipping. You will be able to see a very small indentation on the side of the eye-hole. That is because it was tested in our lab for your safety.The recommendation below is based on several assumptions. Do your own due diligence before installing an anchor anywhere.

M10 bolt: Only to be used in very hard rocks such as Granite (Compressive Strength > 75MPa)

M12 Bolt: Only to be used in medium to high hardness rocks such as Sandstone (Compressive Strength > 30MPa)– EN959:2007, CE3076

- Minimum Breaking Strength of Hanger is 25kN. Although the older versions are marked with 22kN, we guarantee 25kN. We take factor of safety into account with this figure of 25kN. Gipfel hangers are tested for breaking load often and none of them has ever failed under 38kN (the average breaking load has been 40kN) in both recommended direction of loading (radial) as well as in axial direction (Tensile).

- Cutting Strength (Radial Load) in 50MPA test concrete block: 25kN (For Both M10 & M12 Sizes)

- Pull-out strength (Axial load) in 50MPA test concrete block: 25kN (for M12 bolt) and 15kN (for M10 bolt)

User Instructions

Download the PDF

Download the PDF

User Instructions Download the PDF

Download the PDF -

– 304 Stainless Steel for outdoors and indoors use

– Breaking Strength : 45kN, Safe Working Load: 11kN

– These are not yet CE and UIAA certified but we guarantee the performance and breaking load

– Individually tested before shipping for your safety -

High strength rappel ring or descending ring or for use as a component, for climbing or other rope access applications.

Showing all 13 results